Waterproof Backing Board for Bathroom Walls – Ultimate Moisture Protection

Moisture is one of the most persistent challenges in bathroom design and construction. Constant exposure to humidity, steam, and water splashes can lead to structural decay, mold growth, and tile damage if the wall substrate is not properly protected. The Waterproof Backing Board for Bathroom Walls provides a long-term, reliable, and efficient moisture barrier. Designed for professional builders, contractors, and renovators, this material ensures high water resistance, excellent adhesion for tile and stone, and a clean, durable surface suitable for modern wet-area construction.

This article explores the key benefits, technical specifications, cleaning methods, storage conditions, and design philosophy behind waterproof backing boards—making it a comprehensive guide for buyers, installers, and distributors.

A waterproof backing board is a specialized construction panel used as a substrate behind wall finishes in moisture-prone environments. It replaces traditional plasterboard or plywood, which can absorb water and deteriorate over time.

These boards are typically made from high-density extruded polystyrene (XPS) foam or cementitious composites reinforced with fiberglass mesh. They are completely non-absorbent, lightweight, and structurally stable. Once installed behind tiles, stones, or panels, they provide a continuous waterproof layer that prevents water penetration into the wall cavity.

Bathroom and shower walls

Bathtub surrounds

Steam rooms and spas

Laundry rooms and wet zones

Commercial kitchens and locker rooms

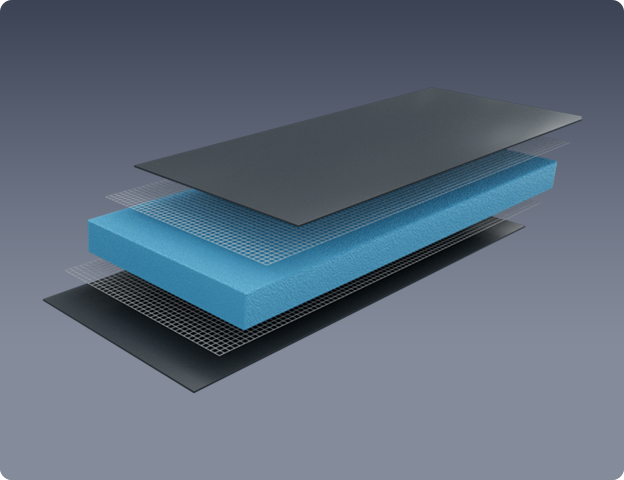

The design concept of waterproof backing boards focuses on combining mechanical strength, water impermeability, and installation efficiency. Every layer in the board serves a specific function:

Core Layer (Waterproof Foam or Cement):

Provides the structural body and primary moisture barrier.

Reinforced Mesh Layer:

Strengthens the board, prevents cracking, and ensures stability under tile weight.

Surface Coating or Skin:

Offers additional protection against alkaline adhesives and thermal expansion.

This three-layer design allows the board to perform efficiently in both residential and commercial projects. Unlike traditional cement boards, waterproof boards are lighter, easier to cut, and free from dust during handling—making installation faster and cleaner.

Completely waterproof and vapor-tight

Excellent adhesion for tile, stone, or decorative finishes

Resistant to mold, rot, and bacteria growth

Lightweight for quick installation

Dimensional stability under temperature and humidity changes

Environmentally friendly and recyclable materials

| Parameter | Specification | Description |

|---|---|---|

| Material Composition | XPS foam core / Cement composite | Waterproof and lightweight structure |

| Density | 30–45 kg/m³ | Provides strength without excess weight |

| Water Absorption | ≤ 0.1% | Fully water-resistant |

| Thermal Conductivity | ≤ 0.035 W/m·K | Enhances energy efficiency |

| Compressive Strength | ≥ 300 kPa | Supports tiles and stone cladding |

| Flexural Strength | ≥ 200 kPa | Prevents cracking or bending |

| Surface Finish | Fiberglass mesh reinforced | Improves tile adhesion |

| Operating Temperature | -50°C to +75°C | Suitable for a wide range of environments |

| Fire Resistance | Class B1 or higher | Meets safety standards for indoor use |

| Panel Dimensions | 600×1200mm, 900×2400mm, custom sizes | Adaptable for various applications |

| Thickness Options | 6mm – 50mm | Depending on wall structure requirements |

These technical parameters are in line with international building material standards, ensuring that each waterproof backing board provides consistent performance in all moisture-exposed environments.

Ensure that the wall surface is flat, clean, and free of dust or oil. Remove old coatings or residues that may affect adhesion.

Measure the installation area and mark the board size. Use a utility knife or fine-tooth saw to cut the panels easily.

Attach the waterproof backing boards to the wall using stainless-steel screws, plastic washers, or appropriate construction adhesive. Maintain tight seams between panels.

Apply a waterproof sealant or joint tape on every seam to ensure a continuous moisture barrier. This step is critical to prevent water leakage.

Once the joints are sealed and dry, apply tile adhesive directly on the board’s surface and install the tiles according to standard practices.

Proper maintenance ensures that waterproof backing boards retain their integrity and performance over time.

Routine Cleaning: Use a soft sponge or cloth with mild soap and warm water to clean exposed areas.

Avoid Harsh Chemicals: Do not use acidic or solvent-based cleaners that could damage the board surface or tile grout.

Mold Prevention: Keep bathroom ventilation adequate to prevent condensation buildup.

Inspection: Periodically inspect joints, corners, and tile grouting for cracks or leaks. Reapply sealant if necessary.

For commercial applications such as hotel bathrooms or spas, use a diluted neutral detergent for periodic cleaning. Avoid high-pressure washing, as it can damage joint seals.

To maintain the product’s performance, waterproof backing boards should be stored and transported under controlled conditions.

Store boards flat on a clean, level surface to prevent deformation.

Avoid direct exposure to sunlight, rain, or high humidity.

Keep storage temperature between 5°C and 40°C.

Do not stack heavy loads on top of the boards to prevent warping or crushing.

Use protective wrapping during transport to avoid scratches or edge damage.

Load boards horizontally and secure them properly to prevent shifting.

Avoid excessive bending during unloading or carrying.

By following proper storage and handling practices, users can ensure that the waterproof backing board retains its full mechanical and waterproofing properties before installation.

Sustainability and safety are central to modern construction materials. High-quality waterproof backing boards comply with international environmental and safety standards, including:

VOC-Free Certification: No harmful volatile organic compounds.

RoHS Compliance: Free from toxic substances like lead or mercury.

ISO 9001 / ISO 14001 Standards: Ensures consistent product quality and environmental management.

Fire Resistance Certification: Meets Class B1 or Class A fire ratings depending on composition.

In addition, the foam core materials are recyclable and energy-efficient, aligning with global green building trends.

Each batch of waterproof backing boards undergoes strict performance testing before shipment. Testing parameters include:

Water absorption and vapor permeability tests

Compressive and flexural strength measurement

Dimensional stability under heat and humidity

Adhesion compatibility with various tile adhesives

Long-term aging simulation in wet environments

Such rigorous testing ensures that every product meets industrial-grade expectations and can withstand prolonged exposure to moisture without degradation.

To cater to different architectural and interior needs, waterproof backing boards can be customized in terms of:

Thickness and Size: From 6mm thin panels for wall cladding to 50mm thick boards for load-bearing applications.

Surface Type: Smooth, rough, or pre-coated surfaces for better adhesive compatibility.

Color Options: Natural grey, blue, or white to match aesthetic preferences.

Edge Profiles: Straight, beveled, or tongue-and-groove edges for seamless installation.

This flexibility makes them ideal not only for bathrooms but also for spas, gyms, public restrooms, and wellness centers.

| Feature | Waterproof Backing Board | Cement Board | Gypsum Board |

|---|---|---|---|

| Water Resistance | Excellent (0.1% absorption) | Moderate | Poor |

| Weight | Lightweight | Heavy | Medium |

| Mold Resistance | High | Medium | Low |

| Ease of Cutting | Easy, low dust | Hard, high dust | Easy |

| Thermal Insulation | Excellent | Moderate | Poor |

| Fire Resistance | Good | Excellent | Moderate |

| Installation Speed | Fast | Slow | Fast |

| Maintenance | Minimal | Medium | High |

This table demonstrates why waterproof backing boards have become the preferred solution for wet-area construction, replacing outdated substrates with superior performance and longevity.

Perfect for home bathrooms, laundry rooms, and kitchens—providing durable, water-tight surfaces that resist daily wear.

Ideal for hotels, fitness centers, spas, and public restrooms, where moisture exposure is constant and durability is critical.

Applied in cleanrooms, laboratories, and food-processing areas requiring hygienic, waterproof wall systems.

Reliable suppliers provide comprehensive after-sales service, including:

Installation guidance and technical documents

On-site consultation for large projects

Maintenance and repair solutions

Product warranty and performance guarantee

End users benefit from long-term product reliability and dedicated support to ensure project success.

With growing awareness of hygiene and sustainability, the demand for waterproof backing boards continues to rise globally. Construction companies and designers prefer them for their low maintenance, high strength, and eco-friendly properties.

Regions like Europe, North America, and Asia-Pacific have seen steady adoption in both residential and commercial sectors. The integration of advanced foam technology, digital manufacturing, and green production methods ensures that waterproof backing boards will remain a leading solution for next-generation construction.

The Waterproof Backing Board for Bathroom Walls represents the future of moisture-resistant construction materials. Its combination of strength, versatility, and sustainability makes it an essential choice for modern bathrooms, kitchens, and wet rooms. From easy installation to outstanding long-term protection, this product delivers consistent results for builders, contractors, and homeowners alike.

When selecting materials for moisture-prone environments, investing in a high-quality waterproof backing board ensures structural safety, durability, and comfort for years to come.

Leave your email address and we will send you the latest product information

Langfang Huaneng Building Materials Co., Ltd. was established on October 24, 1996. It is a subsidiary of Huaneng Zhongtian Energy Conservation Technology Group Co., Ltd.

Copyright © 2025 Langfang Huaneng Building Materials Co., Ltd. All rights reserved

This website uses cookies to ensure you get the best experience on our website.

Comment

(0)