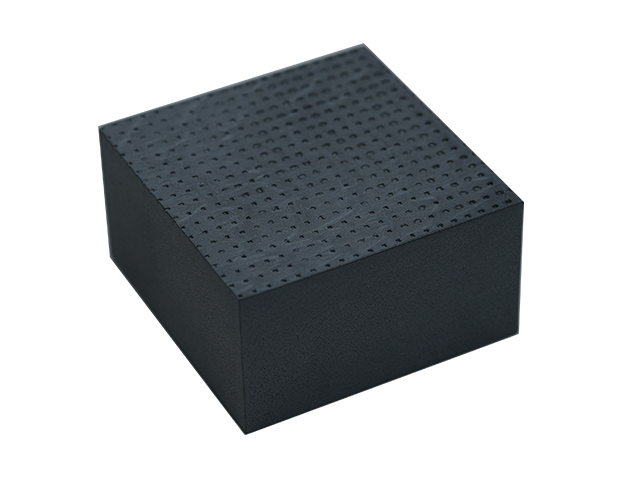

Durable Extruded Boards for Roofing and Cladding

Durable extruded boards have become a go-to solution for modern roofing and cladding applications due to their strength, weather resistance, and versatility. Manufactured through precision extrusion processes, these boards provide consistent thickness, high structural integrity, and superior surface finish, making them suitable for both residential and commercial construction.

They are designed to withstand harsh environmental conditions, resist moisture, and comply with fire and safety regulations. Additionally, many extruded boards meet eco-friendly and sustainable building standards, making them a preferred choice for green construction projects. This article explores the environmental standards, product uses, testing protocols, and maintenance practices for durable extruded boards.

Extruded boards for roofing and cladding are engineered to resist water penetration, humidity, and UV exposure, ensuring long-lasting performance in outdoor environments. Their dense composition prevents warping and swelling, making them ideal for external applications.

Many extruded boards comply with international fire safety standards, such as UL 94, EN 13501, or ASTM E84, offering low flame spread, reduced smoke emission, and heat resistance. Fire-rated boards are essential for commercial buildings, multi-story residential projects, and industrial facilities.

The high flexural and tensile strength of extruded boards ensures durable support for roofing and cladding systems, capable of handling wind loads, mechanical stress, and impact.

Extruded boards are available in various thicknesses, widths, lengths, and surface finishes, allowing architects and builders to achieve customized aesthetics without compromising performance.

Modern extruded boards can be manufactured from recyclable materials and comply with LEED, BREEAM, or other green building certifications, supporting environmentally conscious construction practices.

Boards made from recycled PVC, composite polymers, or thermoplastics reduce environmental impact.

Non-toxic additives ensure safe handling during installation and long-term usage.

LEED Compliance: Supports green building certifications.

ISO 14001: Environmental management system compliance.

RoHS and REACH: Limits hazardous substances in materials.

Dense extruded boards improve thermal insulation, reducing heating and cooling energy consumption.

Reflective surfaces or light colors can reduce heat absorption in roofing applications.

Lightweight extruded boards provide structural support and moisture protection for sloped and flat roofs.

Can be combined with insulation layers for enhanced thermal performance.

Suitable for warehouse roofs, office buildings, and industrial facilities.

Fire-resistant grades improve safety compliance in public spaces.

Provides weatherproof and aesthetic exterior surfaces.

Commonly used for office buildings, retail facades, and residential exteriors.

Can be textured, patterned, or coated for architectural designs.

Applied in partition walls, ceiling panels, and balcony enclosures.

Resistant to chemical exposure, UV radiation, and high impact.

Used in factory walls, laboratory panels, and storage facilities.

Understanding technical parameters is crucial for selecting the right extruded board for roofing or cladding.

| Specification | Typical Value | Application Notes |

|---|---|---|

| Thickness | 3–25 mm | Thicker boards improve insulation and strength |

| Width | 600–1200 mm | Standard for wall and roof installation |

| Length | 2–6 meters | Customizable for specific project needs |

| Density | 1.0–1.6 g/cm³ | Determines structural strength and durability |

| Thermal Conductivity | 0.15–0.25 W/m·K | Contributes to energy efficiency |

| Fire Rating | UL 94 V-0 / EN B1 | Flame-retardant suitable for roofing and cladding |

| Water Absorption | <0.5% | Ensures moisture resistance |

| Flexural Strength | 30–50 MPa | Supports structural loads |

| Surface Finish | Smooth, textured, or patterned | Allows design flexibility |

| Color Options | White, gray, natural, or custom | Supports aesthetic requirements |

Notes:

Boards with higher density and thickness are ideal for roofing under heavy weather conditions.

Smooth surfaces are easy to clean, while textured surfaces offer better aesthetics and anti-slip properties.

Flexural and tensile tests ensure boards can withstand mechanical loads during installation and long-term use.

Conducted per UL 94, EN 13501, or ASTM E84 to verify flame retardancy and smoke emission.

Water absorption tests confirm resistance to swelling and deformation.

Boards are often tested for moisture cycling performance in high-humidity environments.

Thermal conductivity tests ensure effective insulation and energy efficiency.

Suitable for cold storage facilities, residential roofing, and commercial facades.

Boards are analyzed for VOC emissions, hazardous substance content, and recyclability.

Ensure the roof or wall structure is clean, level, and free from debris.

Remove sharp objects that could damage the boards.

Use specialized cutting tools to achieve precise dimensions.

Avoid overheating boards during cutting to prevent warping.

Use adhesives, screws, or mechanical fasteners depending on the application.

Maintain uniform support and spacing to prevent sagging or bending.

Apply joint sealants for waterproofing and weather protection.

For exposed installations, consider UV-resistant coatings or paints.

Regular Cleaning: Wipe surfaces with soft cloths and mild detergents.

Inspection: Check for cracks, warping, or water ingress annually.

Repairs: Replace damaged sections and reseal joints to maintain performance.

Storage: Keep unused boards in cool, dry, ventilated areas, away from direct sunlight.

Cause: Prolonged exposure to heat or moisture.

Solution: Proper storage and installation using reinforced boards.

Cause: Mishandling or contact with abrasive tools.

Solution: Use protective film during transport and careful installation.

Cause: Unsealed edges or low-quality boards.

Solution: Apply waterproof sealants and select boards with low water absorption.

Cause: Using boards without certification.

Solution: Always verify fire rating certificates (UL 94, EN 13501).

| Feature | Extruded Boards | Plywood | Fiber Cement |

|---|---|---|---|

| Moisture Resistance | High | Low | Medium |

| Fire Resistance | High | Low | High |

| Durability | Very High | Medium | Medium |

| Weight | Lightweight | Heavy | Heavy |

| Thermal Insulation | Good | Poor | Poor |

| Surface Finish | Smooth / Customizable | Limited | Rough |

| Lifespan | 15–30 years | 5–10 years | 10–15 years |

Summary: Extruded boards offer superior durability, moisture protection, and flexibility, outperforming traditional materials in most roofing and cladding applications.

Durable extruded boards are a high-performance, eco-friendly solution for modern roofing and cladding. With advantages such as moisture resistance, fire safety, structural strength, and design flexibility, they are suitable for a wide range of residential, commercial, and industrial projects.

By adhering to installation guidelines, conducting proper maintenance, and selecting certified boards, builders and architects can ensure long-term performance and energy efficiency, while meeting environmental standards and safety regulations.

Extruded boards represent a reliable, sustainable, and cost-effective choice, making them an essential material in contemporary construction projects worldwide.

Leave your email address and we will send you the latest product information

Langfang Huaneng Building Materials Co., Ltd. was established on October 24, 1996. It is a subsidiary of Huaneng Zhongtian Energy Conservation Technology Group Co., Ltd.

Copyright © 2025 Langfang Huaneng Building Materials Co., Ltd. All rights reserved

This website uses cookies to ensure you get the best experience on our website.

Comment

(0)