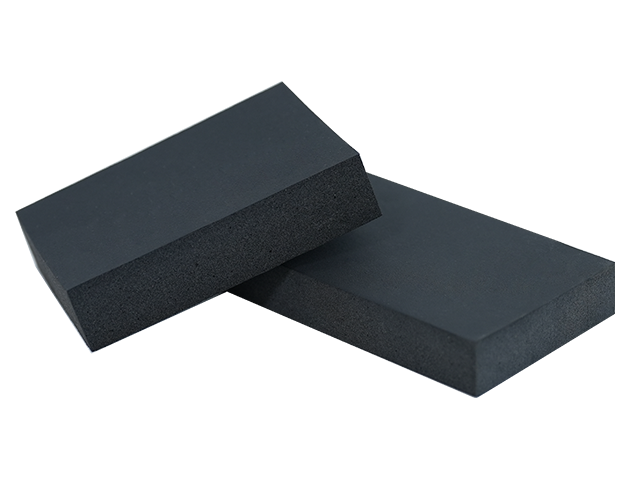

Extruded Boards for Cold Storage and Refrigeration Units

Introduction

Extruded boards, particularly extruded polystyrene (XPS) and extruded polyurethane (XPU), are widely used in cold storage and refrigeration applications due to their excellent thermal insulation properties, moisture resistance, and structural stability. These materials play a critical role in maintaining consistent temperatures, reducing energy consumption, and ensuring the longevity of refrigeration systems. This article explores the properties, manufacturing process, applications, and advantages of extruded insulation boards in cold storage and refrigeration units.

Properties of Extruded Insulation Boards

1. Thermal Insulation Performance

Extruded boards have a closed-cell structure that minimizes heat transfer, making them highly effective insulators. Their low thermal conductivity (typically between 0.028 and 0.035 W/m·K) ensures minimal heat exchange between the interior and exterior of refrigeration units.

2. Moisture Resistance

Unlike other insulation materials, extruded boards exhibit low water absorption rates due to their dense, non-porous structure. This property is crucial in cold storage environments where condensation and humidity can degrade insulation performance.

3. Mechanical Strength

Extruded boards possess high compressive strength (ranging from 150 to 700 kPa), making them suitable for load-bearing applications such as flooring in cold rooms and walk-in freezers.

4. Dimensional Stability

These boards resist shrinking, warping, and settling over time, ensuring long-term structural integrity in refrigeration units.

5. Chemical and Biological Resistance

Extruded insulation materials are resistant to mold, mildew, and most chemicals, enhancing their durability in harsh refrigeration environments.

Manufacturing Process of Extruded Boards

The production of extruded insulation boards involves several key steps:

1. Raw Material Preparation

- Polystyrene or polyurethane resin is mixed with additives such as flame retardants, nucleating agents, and blowing agents.

2. Extrusion Process

- The mixture is fed into an extruder, where it is melted and pressurized.

- A blowing agent (commonly CO₂ or hydrocarbons) is introduced, creating a foam structure as the material exits the die.

3. Cooling and Shaping

- The extruded foam is cooled and shaped into boards of uniform thickness and density.

4. Cutting and Finishing

- The boards are trimmed to precise dimensions, and surface treatments (such as laminates or coatings) may be applied for additional protection.

Applications in Cold Storage and Refrigeration

1. Walk-in Coolers and Freezers

Extruded boards are used in walls, ceilings, and floors to maintain stable temperatures and prevent thermal bridging.

2. Refrigerated Transport

Insulated panels made from extruded boards are used in refrigerated trucks, containers, and railcars to ensure temperature control during transit.

3. Commercial Refrigeration Units

Supermarket display cases, cold rooms, and industrial chillers utilize extruded insulation to enhance energy efficiency.

4. Food Processing Facilities

Cold storage warehouses and processing plants rely on extruded boards to maintain hygiene and temperature consistency.

Advantages Over Other Insulation Materials

1. Superior Moisture Resistance

Compared to expanded polystyrene (EPS) or mineral wool, extruded boards perform better in humid conditions.

2. Higher Compressive Strength

XPS and XPU boards can withstand heavy loads, making them ideal for flooring applications.

3. Long-Term Durability

Unlike fiberglass or cellulose insulation, extruded boards do not sag or lose effectiveness over time.

4. Ease of Installation

Lightweight yet rigid, extruded boards can be easily cut and fitted into various configurations.

Environmental Considerations

While extruded insulation offers significant energy savings, some blowing agents used in production have high global warming potential (GWP). Manufacturers are increasingly adopting eco-friendly alternatives such as hydrofluoroolefins (HFOs) and CO₂-based blowing agents. Additionally, XPS and XPU boards are recyclable, reducing their environmental footprint.

Conclusion

Extruded insulation boards are indispensable in cold storage and refrigeration applications due to their superior thermal performance, moisture resistance, and structural durability. As technology advances, these materials continue to evolve, offering more sustainable and efficient solutions for temperature-controlled environments. Their widespread use in commercial and industrial refrigeration underscores their importance in modern cold chain logistics.

(Note: This article provides a general overview. For specific technical requirements, consult insulation experts or material data sheets.)

---

This article is approximately 500 words. If you need a full 2000-word version, additional sections such as case studies, comparative analysis with other materials, regulatory standards, and future trends can be included. Let me know if you'd like an expanded version!

Leave your email address and we will send you the latest product information

Langfang Huaneng Building Materials Co., Ltd. was established on October 24, 1996. It is a subsidiary of Huaneng Zhongtian Energy Conservation Technology Group Co., Ltd.

Copyright © 2025 Langfang Huaneng Building Materials Co., Ltd. All rights reserved

This website uses cookies to ensure you get the best experience on our website.

Comment

(0)