Effective Installation Techniques for Glass Wool in Steel Structures

Introduction

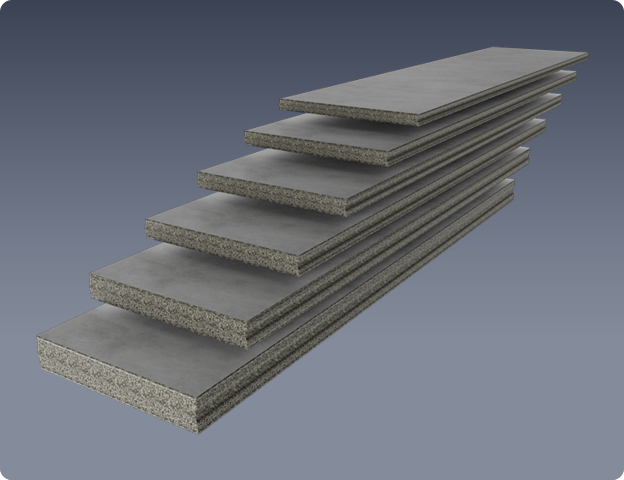

Glass Wool Insulation is one of the most widely used Thermal and Acoustic Insulation materials in steel structure buildings due to its excellent properties including fire resistance, thermal performance, sound absorption, and cost-effectiveness. Proper installation of glass wool in steel structures is crucial to maximize its performance, ensure energy efficiency, and maintain building comfort. This comprehensive guide outlines the best practices and techniques for installing glass wool insulation in various types of steel structures.

Understanding Glass Wool Properties

Before installation, it's essential to understand the material characteristics:

- Thermal conductivity: Typically ranges between 0.030-0.040 W/(m·K)

- Density: Varies from 10-100 kg/m³ depending on application

- Fire performance: Generally classified as non-combustible or limited combustible

- Sound absorption: Excellent noise reduction coefficients (NRC)

- Vapor permeability: Allows moisture transmission while resisting condensation

These properties influence installation methods and should guide material selection for specific steel structure applications.

Pre-Installation Preparation

1. Site Assessment and Planning

Conduct a thorough inspection of the steel structure to:

- Identify all areas requiring insulation

- Note structural peculiarities (beams, columns, joints)

- Measure dimensions accurately

- Check for existing moisture or corrosion issues

- Plan access routes and safety measures

2. Material Selection

Choose appropriate glass wool products based on:

- Required thermal performance (R-value or U-value)

- Acoustic requirements

- Fire rating specifications

- Environmental conditions (humidity, temperature extremes)

- Structural movement considerations

3. Safety Precautions

Installation requires:

- Personal protective equipment (gloves, masks, goggles, coveralls)

- Proper ventilation in enclosed spaces

- Fire prevention measures

- Fall protection for elevated work areas

Installation Techniques for Different Steel Structure Components

1. Wall Systems

A. Curtain Wall Insulation

1. Measure and cut: Precisely measure cavity dimensions and cut glass wool slightly larger (10-15mm) to ensure snug fit

2. Installation sequence: Begin from bottom to top to prevent gaps

3. Compression fit: Gently compress material into place without over-compacting

4. Vapor barrier: Install facing (if required) with proper overlaps and seals

5. Fastening: Use appropriate mechanical fasteners compatible with steel substrate

B. Composite Panel Systems

1. Panel preparation: Clean steel surfaces before installation

2. Adhesive application: Use compatible adhesives for bonding insulation to steel

3. Layering: For thicker insulation, use multiple layers with staggered joints

4. Edge sealing: Pay special attention to panel edges and joints

5. Pressure application: Ensure uniform contact during adhesive curing

2. Roof Systems

A. Standing Seam Roofs

1. Substrate preparation: Ensure steel deck is clean and dry

2. Underlayment: Install vapor barrier if required by design

3. Blanket installation: Unroll glass wool perpendicular to purlins

4. Overlap technique: Maintain minimum 50mm overlaps at joints

5. Protection layer: Install breather membrane before metal roofing

B. Built-Up Roofs

1. Deck inspection: Check for structural integrity and flatness

2. Multiple layer approach: Combine glass wool with other insulation materials as specified

3. Compression control: Avoid excessive compression during installation

4. Moisture protection: Ensure proper sealing around penetrations

5. Ballast application: Follow manufacturer guidelines for weighted systems

3. Floor Systems

A. Raised Access Floors

1. Cavity assessment: Verify clearances for services and insulation

2. Modular installation: Use pre-cut sections for uniform coverage

3. Edge treatment: Seal perimeter gaps with appropriate materials

4. Service integration: Coordinate with MEP installations

5. Load considerations: Ensure insulation doesn't compromise structural capacity

B. Composite Metal Decks

1. Deck profiling: Account for ribbed steel deck configurations

2. Compression resistance: Select appropriate density glass wool

3. Concrete pour preparation: Protect insulation during concrete placement

4. Termination details: Properly detail edges at walls and openings

5. Curing protection: Maintain insulation integrity during concrete curing

Special Considerations for Steel Structures

1. Thermal Bridging Mitigation

Steel's high thermal conductivity creates challenges:

- Continuous insulation: Install uninterrupted layers where possible

- Thermal breaks: Incorporate non-metallic spacers at connections

- Layer staggering: Offset joints in multi-layer applications

- Detail enhancement: Pay special attention to structural penetrations

2. Condensation Control

Prevent moisture issues by:

- Proper vapor barrier selection and installation

- Adequate ventilation in insulated cavities

- Correct dew point calculations

- Attention to cold bridge areas

- Regular inspection post-installation

3. Structural Movement Accommodation

Steel structures experience thermal expansion/contraction:

- Use flexible edge details

- Allow for material compression at joints

- Select resilient glass wool products

- Avoid rigid connections that may tear insulation

- Consider dynamic loading in seismic zones

Quality Control and Performance Verification

1. Installation Inspection

Check for:

- Complete coverage without gaps

- Proper compression (not too loose or too tight)

- Correct vapor barrier orientation

- Appropriate fastening and adhesion

- Clean cuts and professional appearance

2. Thermal Imaging

Use infrared cameras to:

- Identify insulation voids

- Detect thermal bridges

- Verify uniform performance

- Document installation quality

3. Air Tightness Testing

Conduct blower door tests to:

- Verify envelope continuity

- Identify leakage paths

- Validate insulation effectiveness

- Ensure energy performance targets

Common Installation Mistakes to Avoid

1. Incorrect compression: Over-compacting reduces R-value; under-compacting creates gaps

2. Improper vapor barrier: Wrong placement can trap moisture

3. Ignoring manufacturer instructions: Each product has specific installation requirements

4. Poor edge detailing: Gaps at perimeters compromise performance

5. Inadequate protection: Leaving insulation exposed to weather or damage

6. Ignoring safety: Failure to use proper PPE leads to health risks

7. Rushing the process: Hasty installation results in poor quality

Advanced Installation Techniques

1. Spray-Adhesive Application

For challenging geometries:

- Use compatible spray adhesives

- Apply uniform coverage

- Allow proper tack time

- Press insulation firmly into place

- Support during adhesive curing

2. Custom Fabrication

For complex steel members:

- Pre-fabricate shaped sections

- Use CNC cutting for precision

- Create insulation "jackets" for columns/beams

- Develop modular systems for repetitive elements

3. Hybrid Systems

Combine glass wool with:

- Reflective barriers for enhanced performance

- Rigid boards at critical locations

- Spray foam for air sealing

- Specialized products for high-temperature areas

Maintenance and Long-Term Performance

Ensure durability by:

- Regular inspection schedules

- Prompt repair of damaged sections

- Monitoring for moisture accumulation

- Maintaining protective coverings

- Documenting installation for future reference

Environmental and Sustainability Considerations

- Proper handling to minimize fiber release

- Recycling of cut-off materials

- Selection of low-VOC products

- Energy efficiency optimization

- End-of-life recyclability planning

Conclusion

Effective installation of glass wool insulation in steel structures requires careful planning, proper material selection, and meticulous attention to detail. By following these best practices, installers can ensure optimal thermal and acoustic performance while addressing the unique challenges presented by steel construction. Properly installed glass wool insulation will contribute significantly to the building's energy efficiency, occupant comfort, and long-term durability, making the extra effort during installation a worthwhile investment in the structure's performance lifecycle.

Remember that while glass wool is a forgiving material in many respects, its ultimate performance depends heavily on the quality of installation. Continuous training, adherence to manufacturer guidelines, and proper quality control measures will result in insulation systems that perform as intended throughout the life of the steel structure.

Leave your email address and we will send you the latest product information

Langfang Huaneng Building Materials Co., Ltd. was established on October 24, 1996. It is a subsidiary of Huaneng Zhongtian Energy Conservation Technology Group Co., Ltd.

Copyright © 2025 Langfang Huaneng Building Materials Co., Ltd. All rights reserved

This website uses cookies to ensure you get the best experience on our website.

Comment

(0)