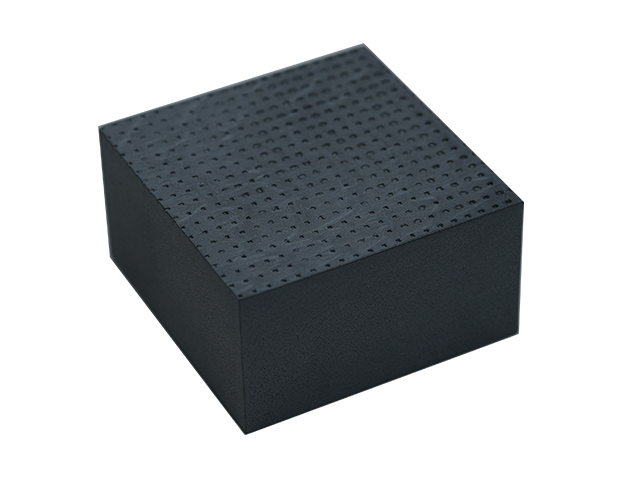

Waterproof and Heat-Insulating Graphite Extruded Board – High-Performance Construction Insulation

Waterproof and heat-insulating graphite extruded boards are premium insulation materials designed to deliver superior thermal efficiency, moisture resistance, and long-term durability. Produced from high-density extruded polystyrene (XPS) enhanced with graphite particles, these boards provide lower thermal conductivity, higher compressive strength, and excellent water resistance compared to standard XPS boards.

These boards are ideal for residential, commercial, and industrial construction projects, including roofs, walls, floors, and industrial insulation systems. Lightweight yet robust, they are easy to transport, handle, and install, ensuring efficiency and performance in energy-saving and waterproofing applications.

Graphite extruded boards are engineered to combine strength, insulation, and moisture protection in a single panel.

Graphite particles reduce radiant heat transfer, improving thermal efficiency.

Provides uniform heat reflection and contributes to energy savings.

Ensures compressive strength and structural stability.

Resistant to deformation, shrinkage, and long-term stress.

Smooth, sealed surface prevents water absorption and mold growth.

Suitable for wet environments such as basements and roofs.

Simplifies handling, cutting, and installation.

Compatible with adhesives, mechanical fasteners, or combination methods.

Graphite extruded boards are available in various sizes, thicknesses, and densities to meet diverse construction needs.

| Parameter | Specification | Benefit |

|---|---|---|

| Material | High-density XPS with graphite | Combines thermal efficiency with strength |

| Thickness | 20–120 mm | Flexible use for walls, floors, and roofs |

| Density | 35–45 kg/m³ | High compressive strength for load-bearing applications |

| Thermal Conductivity | 0.027–0.033 W/m·K | Reduces energy loss |

| Water Absorption | ≤ 0.5% | Effective moisture resistance |

| Board Size | 600 × 1200 mm standard | Easy to transport and install |

| Fire Rating | Class B1 (optional) | Enhances safety |

| Surface Finish | Smooth or textured | Optimized for adhesion and finishing |

Proper storage is essential to maintain performance and longevity:

Dry and Ventilated Area

Store boards away from rain, high humidity, or standing water.

Prevents moisture absorption and mold formation.

Avoid Direct Sunlight

Prolonged exposure may affect surface integrity and color.

Keep boards covered or shaded.

Flat and Stable Position

Store on a level surface to avoid warping or bending.

Avoid placing heavy objects on top.

Temperature Considerations

Recommended storage temperature: -10°C to 50°C.

Avoid extreme heat or freezing conditions that may compromise structure.

Ensuring consistent quality is critical to building safety and insulation efficiency.

Only high-density XPS granules with verified graphite content are used.

Ensures thermal performance, compressive strength, and moisture resistance.

Continuous monitoring of temperature, pressure, and flow during extrusion.

Guarantees uniform density, thickness, and structural integrity.

Compressive strength, thermal conductivity, water absorption, and fire resistance tested per ISO and ASTM standards.

Guarantees reliable long-term performance.

Boards inspected for surface quality, edge integrity, and labeling accuracy.

Ensures safe delivery without cracks, scratches, or deformation.

Proper installation ensures maximum insulation performance:

Surface Preparation

Ensure surfaces are clean, dry, and level.

Remove debris, dust, and sharp objects that may damage boards.

Cutting and Shaping

Use utility knives, hot wire cutters, or saws for precise cuts.

Ensure straight edges for tight seams.

Placement

Lay boards directly on the surface (walls, floors, roofs).

Stagger joints to prevent heat bridges.

Fixing

Secure boards using adhesives, mechanical fasteners, or both.

Ensure flush alignment and level placement.

Sealing Joints

Apply sealant or joint tape to enhance waterproofing.

Inspect for gaps or misalignment.

Graphite extruded boards are low-maintenance, but proper care ensures long-term durability:

| Task | Frequency | Method / Notes |

|---|---|---|

| Surface Cleaning | As needed | Wipe with a damp cloth; avoid abrasive cleaners |

| Joint Inspection | Every 6–12 months | Check for cracks or sealant deterioration |

| Moisture Check | Periodically | Ensure no water infiltration behind boards |

| Protective Coating | Optional | Apply in high-wear or outdoor areas |

Tips:

Avoid strong chemical cleaners that may damage surface integrity.

Reapply sealant at joints if signs of water seepage are observed.

Graphite extruded boards are suitable for multiple construction scenarios:

Residential Buildings: Roof and wall insulation to reduce energy costs.

Commercial Projects: High-performance insulation for offices, hotels, and shopping centers.

Industrial Facilities: Cold storage, refrigeration units, and factories.

Civil Engineering: Road platforms, bridges, and landscaping insulation.

Enhanced Thermal Performance: Graphite particles reduce radiant heat transfer.

High Compressive Strength: Supports heavy loads in industrial or multi-story construction.

Moisture Resistance: Prevents mold, decay, and structural damage.

Lightweight and Easy Installation: Reduces labor costs and installation time.

Long-Term Dimensional Stability: Maintains performance for decades.

Proper packaging ensures safe transport and handling:

| Packaging Type | Quantity | Notes |

|---|---|---|

| Individual Wrap | 5–20 pcs per pack | Suitable for small-scale projects |

| Bulk Carton | 50–200 pcs | Ideal for large construction sites |

| Protective Film | Optional | Prevents scratches or moisture |

| Palletized Loads | Standard | Facilitates safe transport and storage |

Transport Recommendations:

Avoid stacking heavy objects.

Store in dry, shaded areas.

Handle carefully to prevent edge or surface damage.

Waterproof and heat-insulating graphite boards are valued for thermal efficiency, strength, and ease of installation:

Architect (USA):

“Graphite boards reduced energy costs while maintaining structural integrity on the roof.”

Construction Manager (Germany):

“Installation was smooth, and the boards resisted moisture perfectly in basement walls.”

Industrial Engineer (Australia):

“Excellent performance for cold storage; durable, water-resistant, and easy to handle.”

DIY Homeowner (UK):

“Boards are lightweight and simple to cut, achieving professional-level insulation results.”

Waterproof and heat-insulating graphite extruded boards are versatile, high-performance insulation solutions. Their graphite-enhanced core, high compressive strength, and moisture resistance make them ideal for residential, commercial, and industrial applications.

By following proper storage, installation, and maintenance guidelines, these boards deliver long-lasting energy efficiency, structural stability, and cost-effective insulation, making them a trusted choice for global construction projects.

Leave your email address and we will send you the latest product information

Langfang Huaneng Building Materials Co., Ltd. was established on October 24, 1996. It is a subsidiary of Huaneng Zhongtian Energy Conservation Technology Group Co., Ltd.

Copyright © 2025 Langfang Huaneng Building Materials Co., Ltd. All rights reserved

This website uses cookies to ensure you get the best experience on our website.