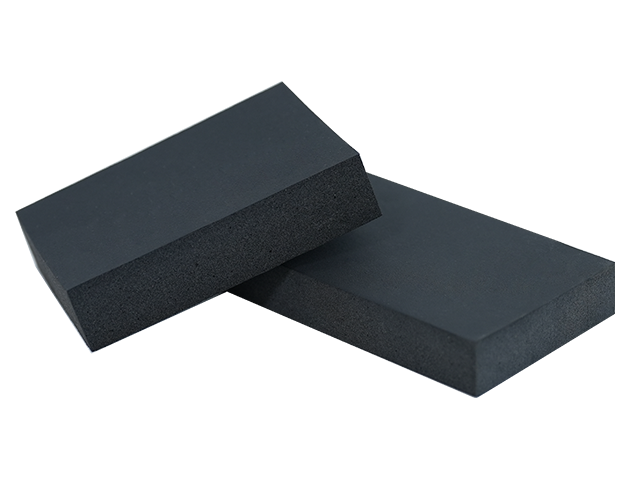

Elastic Cushioning Rubber-Plastic Sponge Board: Efficient, Eco-Friendly, and Quick-to-Install Insulation Solution

The Elastic Cushioning Rubber-Plastic Sponge Board is a versatile material designed for shock absorption, vibration damping, thermal insulation, and protective applications. Constructed from premium rubber and plastic composites, it offers excellent elasticity, durability, and lightweight handling, making it ideal for industrial machinery, construction, automotive applications, and packaging protection.

This board not only ensures long-term performance and structural integrity but also meets international environmental standards, making it an eco-friendly and sustainable choice for modern construction and manufacturing needs.

Provides high elasticity to absorb shocks and reduce impact forces.

Maintains shape and performance after repeated compression cycles.

Protects sensitive equipment, packaging, and structural components from mechanical damage.

Acts as a thermal insulator, reducing energy loss in buildings, pipelines, and industrial equipment.

Offers acoustic damping, decreasing noise and vibration in machinery and vehicles.

Waterproof, wear-resistant, and fire-retardant properties.

Meets international environmental and safety standards (e.g., RoHS, REACH).

Long-lasting performance in indoor and outdoor applications.

| Feature | Specification | Standard |

|---|---|---|

| Density | 40–150 kg/m³ | ASTM D3574 |

| Hardness | 20–50 Shore A | ISO 7619 |

| Fire Rating | UL94 V-0 / B1 | IEC 60695-11-10 |

| Thermal Conductivity | 0.035–0.045 W/m·K | ASTM C518 |

| Vibration Damping | High | ISO 10846 |

Made from recyclable rubber and plastic composites.

Free from harmful halogens, heavy metals, and toxic additives.

Minimizes environmental impact during production, installation, and disposal.

| Standard | Compliance |

|---|---|

| RoHS | Restriction of Hazardous Substances |

| REACH | Registration, Evaluation, Authorization, and Restriction of Chemicals |

| ISO 14001 | Environmental Management System Certification |

| UL94 | Flammability Testing |

By adhering to these standards, the board ensures safety, sustainability, and regulatory compliance, making it suitable for green building projects and eco-conscious manufacturing.

The Elastic Cushioning Rubber-Plastic Sponge Board is suitable for a wide range of industries and applications:

| Industry | Application |

|---|---|

| Industrial | Machinery pads, conveyor belts, vibration damping, protective padding |

| Construction | Wall insulation, floor underlays, acoustic panels, anti-vibration mats |

| Automotive | Engine mounts, interior noise reduction, bumper pads |

| Packaging | Protective inserts for electronics, glassware, and fragile items |

| HVAC Systems | Duct insulation, vibration control, thermal protection |

Proper installation ensures optimal performance and longevity of the sponge board.

| Tool / Material | Purpose |

|---|---|

| Measuring Tape | Accurate measurement of installation area |

| Utility Knife / Scissors | Cutting boards to required size |

| Adhesive / Mechanical Fasteners | Secure installation to walls, floors, or equipment |

| Protective Gear | Gloves and masks to prevent skin irritation or dust inhalation |

| Roller / Press | Ensure smooth attachment and even surface contact |

Measure and Mark: Measure the area accurately and mark the cutting lines.

Cut Boards: Use a sharp utility knife or scissors for precise sizing.

Position Boards: Place boards with facing side outward; ensure tight joints with minimal gaps.

Secure Boards: Apply adhesive or fasteners as per surface type and manufacturer guidelines.

Seal Edges (Optional): Use tape or sealant to prevent moisture ingress and ensure long-term performance.

Inspection: Verify alignment, adhesion, and integrity before operational use.

Pre-cut boards to reduce on-site labor.

Use lightweight boards to minimize handling effort.

Maintain consistent pressure when pressing boards onto adhesive surfaces.

Follow manufacturer instructions for specific adhesives or fasteners.

Regular maintenance ensures elasticity, thermal insulation, and protective performance remain optimal.

| Task | Frequency | Method |

|---|---|---|

| Visual Inspection | Every 6 months | Check for tears, compression, or water damage |

| Cleaning | Quarterly | Use a soft brush or vacuum; avoid excessive water |

| Adhesive or Fastener Check | Annually | Reapply adhesive or tighten fasteners if loose |

| Performance Assessment | Every 2–3 years | Evaluate thermal insulation, vibration damping, and elasticity |

Use dry cloths or vacuums for routine cleaning.

For minor stains, light damp cloths can be used on the facing layer.

Avoid chemical cleaners or prolonged water exposure, which may compromise board performance.

Inspect boards after cleaning for damage or wear.

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Sagging or deformation | Excessive weight or compression | Reinstall with proper support and spacing |

| Reduced thermal insulation | Moisture absorption or gaps | Ensure waterproof facing; seal gaps with tape |

| Loss of elasticity | Aging or UV exposure | Replace affected sections; use UV-protected variants |

| Surface tears or abrasion | Mechanical impact | Apply protective layer or replace damaged portion |

| Noise reduction decline | Improper fitting or uneven installation | Realign boards; ensure flush placement |

Clients highlight the material’s ease of use, performance, and sustainability:

“The rubber-plastic sponge boards improved vibration control in our production line dramatically.” – Industrial Engineer

“Installation was fast and straightforward, with minimal labor required.” – Construction Contractor

“Our vehicles’ interior noise levels decreased noticeably after installation.” – Automotive Engineer

“Eco-friendly and compliant with environmental standards – perfect for our green building project.” – Facility Manager

The Elastic Cushioning Rubber-Plastic Sponge Board is a high-performance, versatile, and environmentally friendly insulation and protective solution. Its elasticity, thermal and acoustic properties, and ease of installation make it ideal for industrial, automotive, construction, and packaging applications.

By following proper installation, maintenance, and safety practices, users can maximize lifespan and functional performance while ensuring compliance with international environmental and safety standards.

Leave your email address and we will send you the latest product information

Langfang Huaneng Building Materials Co., Ltd. was established on October 24, 1996. It is a subsidiary of Huaneng Zhongtian Energy Conservation Technology Group Co., Ltd.

Copyright © 2025 Langfang Huaneng Building Materials Co., Ltd. All rights reserved

This website uses cookies to ensure you get the best experience on our website.